Vibration noise-absorbing materials for industrial rotors

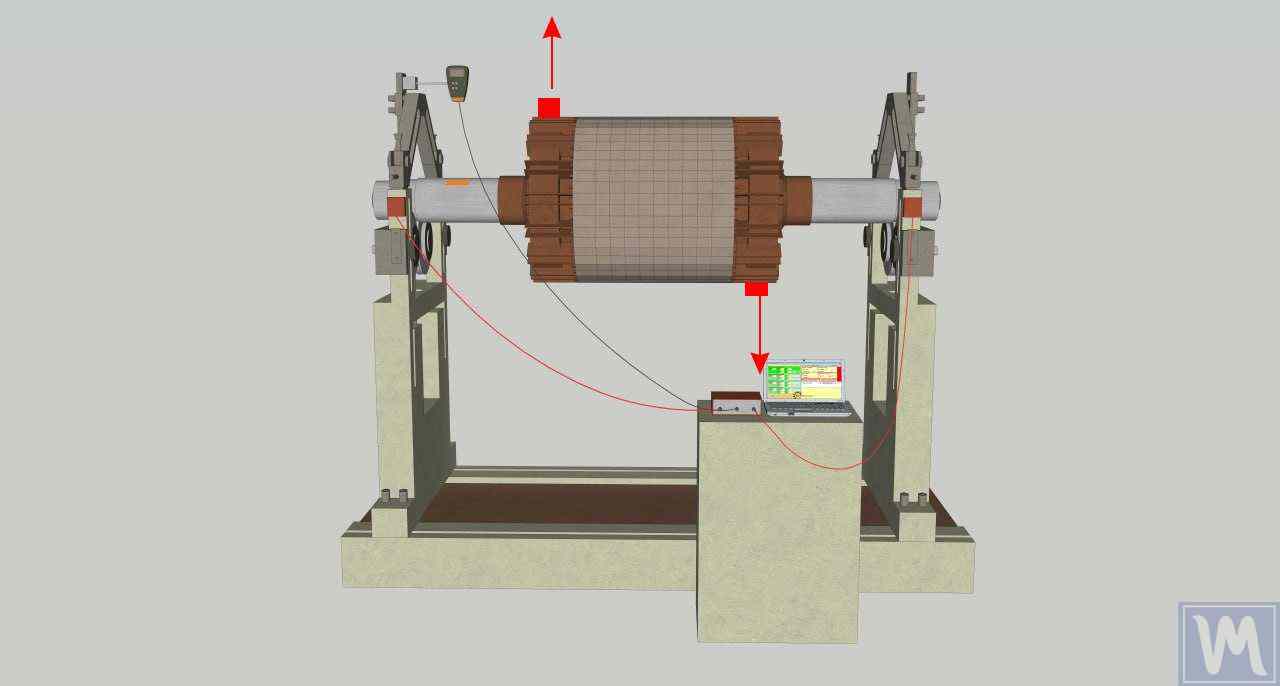

Balanset-1A: The Ultimate Rotor Balancing Device

When it comes to ensuring optimal performance in machinery, rotor balancing is critical. The Balanset-1A is a state-of-the-art device that simplifies this complex task. This article explores its features, advantages, and how to effectively balance a horizontal rotor using this innovative device.

Compactness and Portability

The Balanset-1A is designed for convenience and mobility. Housed in a compact and durable case, it is easy to transport, making it perfect for fieldwork or on-site operations. This portability is essential for professionals who frequently work with equipment outside of stationary environments, such as manufacturing sites.

Intuitive Software

One of the standout features of the Balanset-1A is its intuitive software. When connected to a laptop, users are greeted with a user-friendly interface that provides step-by-step instructions for setup and balancing. The software automatically calculates the corrective weights and their installation angles, allowing even novices to achieve accurate results.

Multifunctionality

The Balanset-1A serves dual purposes as both a vibration meter and a balancing device. In vibration meter mode, users can monitor overall vibration levels, generate spectra, and analyze harmonics to get a comprehensive understanding of the machine’s condition. In balancing mode, it offers calculations for mass and angles of weights in one or two planes.

High Measurement Accuracy

Accuracy is paramount in rotor balancing, and the Balanset-1A does not disappoint. With a phase measurement accuracy of В±1В° and vibration readings accurate to В±5%, this device meets high industry standards. This precision is vital for tasks ranging from balancing fans to tuning industrial machine rotors.

Customizable Options

The Balanset-1A comes equipped with various options that allow it to be tailored to specific tasks. Users can select modes that display polar diagrams or utilize the built-in calculator to assess permissible imbalance according to ISO 1940. This adaptability makes it suitable for a wide range of applications, from straightforward to more complex balancing challenges.

Ease of Learning and Use

No advanced knowledge in vibration diagnostics is required to operate the Balanset-1A. The program is streamlined, making it accessible even for beginners in the field. Additionally, the device archives all data, facilitating easy review of results and learning from past sessions.

Support for Serial Balancing

The Balanset-1A is ideally suited for serial production environments where consistent balancing of numerous identical rotors is necessary. The device allows users to save and retrieve data from previous sessions, significantly speeding up the process and reducing labor costs.

Operation Without a Tachometer

In situations where precise phase angle measurement is not critical, the Balanset-1A can operate without a tachometer. It will still provide a general vibration level, which is convenient for quick diagnostics. However, for instances requiring accurate data, a tachometer can be incorporated for enhanced measurements.

Quality Assurance and Reliability

Backed by a one-year warranty, the Balanset-1A comes with the assurance of quality and reliability. Vibromera offers technical support and assistance in case of failures, making it a dependable choice for users who rely on the device for long-term operation.

Cost-Effectiveness and Accessibility

With a relatively low price compared to similar devices on the market, the Balanset-1A offers an excellent balance of cost and quality. It is accessible to both large manufacturing facilities and small workshops, making it a wise investment for those looking to enhance product quality with minimal expenditure.

How Do You Balance a Horizontal Rotor?

Balancing a horizontal rotor using the Balanset-1A involves the following steps:

- Set up the device and connect it to your laptop, ensuring the software is running.

- Follow the on-screen instructions to input the rotor’s specifications.

- Attach the sensors to the rotor and perform a test run to gather initial vibration data.

- Analyze the results using the software, which will indicate the necessary corrective weights and their positions.

- Install the calculated weights on the rotor as per the software’s recommendations.

- Conduct a final assessment to ensure the rotor is balanced to the required standards.

With the Balanset-1A, balancing horizontal rotors becomes a straightforward task, ensuring your machinery operates at peak efficiency.

[b]Contact Information:[/b]

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on eBay

Leave an answer

You must login or register to add a new answer.